|

Control solution

1. Global scheduler

To compensate for the deficiencies of both hierarchical and heterarchical manufacturing control systems, the concept of Holonic Manufacturing Systems was chosen for designing and implementing a networked robotized assembly system, featuring intelligence, product tracking with integrated quality control, and fault-tolerance.

The model was taken from automated manufacturing cells containing one or more control units, processing machines, material handling devices (robots) and other pieces of equipment that work together to perform the required operations on the incoming work pieces. By grouping the hardware and software parts of the system based on their functions and applying both the holonic concept and the decentralized control approach, the proposed architecture is considered to control the multiple-robot networked assembly system.

The flow of information between control units is always bi-directional due to the decentralized nature of the architecture and the application of the holonic concept of cooperation. This assembly structure is derived from the generic manufacturing one, formed by four types of entities:

-

A layer of Order Holons (OHp(δ),1≤p≤P) of variable depth, corresponding to assembly plans computed off line for the Pfinal products.

- Two types of Resource Holons:

- Robot (or Material Assembly) Holons (RHl',q), formed by all robot manipulators, grippers and tools together with their controllers, responsible for mounting, fixing and fastening assembling components, and for moving their arm-mounted cameras in picture-taking points where the products are visually inspected.

- Sensory (Material Tracking & Checking) Holons (SHl'',q), formed by all machine vision systems and magnetic code RD/WR devices respectively used for component / subassembly position and geometry control and product tracking on pallets.

-

A System Monitoring and Database (SMDB) entity, responsible for monitoring the number of jobs and availability of resources in the system, and for keeping track of the already executed operations and assembly jobs.

-

A Global Assembly Scheduler (GAS), generating basic and alternate assembly plans for all batch products in the form of OH. An algorithm base is embedded into a knowledge-based system (KBS). An inference engine in the KBS controls, according to a forward chaining control strategy, the procedures of: triggering production rules, switching to algorithmic schedule generation, and holonic fault-tolerant task allocation.

The Global Assembly Scheduler computes off-line the OHp(δ),1≤p≤Pat batch level rending assembly plans APp(δ) available for products Ap,p∈P. One operation Oi∈O in the pth OH is executable if all resources needed to carry it out are defined as operational by at least one APp(δ). Operation Oi∈O is schedulable at time t, if

2. On-line/Off-line aspects

In the proposed architecture, the GAS is basically a control unit that delivers (optimal) schedules for the material assembly and conditioning equipment when the system is operating under normal conditions. The main GAS computing occurs off-line: a set of jobs (assemblies) is to be executed with on line control by a set of robot-vision resources (processors), eventually minimizing (maximizing) an imposed performance function. An assembly job (product) may consist of a number of operations. All assembly parameters are assumed to be known a priori; each operation is to be executed by at most one robot or camera at a time. Initially, all robots are operational.

Based on its global image of the assembly system and the number of jobs in progress at any given time, the GAS computes the schedules in the form of assembly plans (OHs), but it does not impose its schedule to any of the individual robot-vision RH, SH resources. The schedules delivered by the GAS are treated as recommendations by the decision-making entities. If a problem occurs in the manufacturing process(ex: a controller breaks down) the system changes to another type of operation, online operation, where holons interact with each other, trying to solve the problem in the best way.

3. Holon description

The holonic concept originated from the work of the Hungarian author and philosopher Arthur Koestler, who proposed the term holon to describe a basic unit of organization in biological and social systems [Koestler 1968]. Two important properties of holons make the holonic concept a suitable modelling tool for use in the design of both manufacturing and material-handling systems. First, autonomy grants holons the right to make decisions without consulting any supervising entity. Second, cooperation permits holons to communicate with other peer holons to develop mutually acceptable plans and execute them. In manufacturing and material-handling systems the holon is a basic entity composed of a software part, which represents the logic, and a hardware part, the machine.

An assembly planAPp(δ) of a product Ap is embedded in a resulting Order Holon OH as a vector of triplets, each specifying operation number Oi, processing time tiδ of operation Oi using assembly plan APp(δ), and set of resources RHl',q to process the operation Oi:

APp(δ)=[...,(Oi,ti(δ),Ri(δ)),...],1≤i≤f,

where Rp(δ)={r1q|i(δ),...,r5q|i(δ)},q∈Ql,l∈L,1≤i≤f. The basic assembly plan with Of as final operation is denoted by δ=b, whereas δ=a are alternative plans (b=0,a=1,2,...).

Experiments showed that in most cases ti(b)≤ti(a).

In the designed holonic mechanism, the assembling and control operations are executed by the Robot and Sensory resource Holons RSH after an algorithmic evaluation of the requests received from the OHs. The individual assembly schedules APj(δ),1≤p≤P delivered by the GAS are evaluated by the current OH layer and HOLON_MODE (real time) rule set in the inference engine, and awarded by:

- choosing the lowest cost schedule of available resources received, or by

- reallocating resources if the scheduled ones are not operational (due to break downs), or by

- rescheduling operations upon negative result of execution tracking or visual quality control.

The final decision related to an assembly job is made by the OH manager of the job after receiving offers from the R(S)H entities in the system. If necessary, changes in off line computed schedules will be made by R(S) holons based on fault-tolerant cooperation protocols.

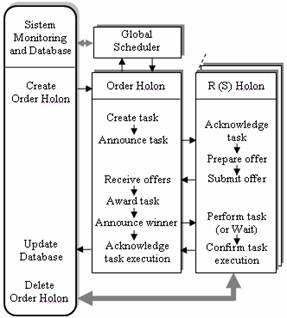

Task allocation in the holonic operation mode.

For each new job, there is a dedicated holon having specific responsibilities, including the right to make the final decision about which resources will execute the included operations. This decision is made by the manager of the new job - the associated OH based on the proposals received from the RSHs and GAS.

The RSH's offers have their own decision embedded in them, since they are weighted corresponding with their status  and future workload. When a new job enters the system, the first entity to acknowledge it is the SMDB which creates a corresponding OH. This OH announces the new operation tasks to the RSHs and the GAS, sends all the information related to the new assembly type, and sets a deadline for receiving the material conditioning (e.g. transport & manipulation, fastening,…,inspecting) offers. and future workload. When a new job enters the system, the first entity to acknowledge it is the SMDB which creates a corresponding OH. This OH announces the new operation tasks to the RSHs and the GAS, sends all the information related to the new assembly type, and sets a deadline for receiving the material conditioning (e.g. transport & manipulation, fastening,…,inspecting) offers.

4. Fault tolerance

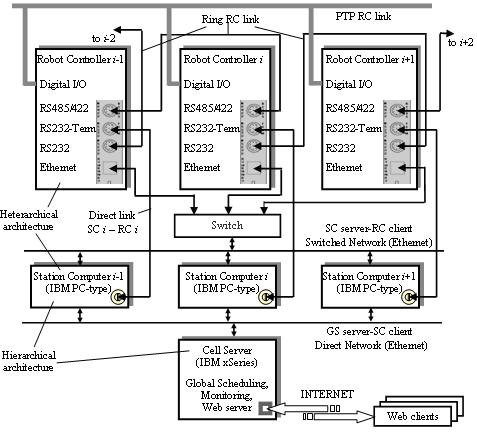

Fault-tolerance is provided to the cell communication system by a multiple connection LAN, providing redundancy at both Station Controller level (a break down of a Robot Controller is detectable, the production tasks can be rescheduled to the remaining valid units for graceful degraded behaviour) and Station Computer level (replication of data bases for the IBM PC-type device terminals, reassignment of computers in case of break downs).

The cluster of SCs implementing the Order Holon (OH) and Material Handling Holon (MHH) holonic control layers is interconnected to the process devices (Robot Controllers) via a SC server – RC client Switched Ethernet Network, creating a heterarchical fault-tolerant architecture:

- the failure of a Station Controller is detected by continuous monitoring via the direct serial links SCi – RCi and determines in consequence the rescheduling of jobs for the (n – 1) remaining valid Robot Controllers j, 1 ≤ j ≤ n, j ≠ i.;

- if one of the Station Computers is down, its role is taken over by the remaining (n – 1) workstations, as each SC data base is replicated and updated on line in all the other (n – 1) ones;

- if the switch is down, the heterachical communication between the SC and the RC clusters still operates via the direct links SCi – RCi and the Ring RC link

Finally, the vital inter-operational conditioning between device tasks (mutual exclusion, synchronization) is provided by a cross- connection I/O network.

Fault-tolerant communication architecture.

5. Implementing the fault tolerance

Because the offline scheduling algorithm takes a short time to compute a schedule even for a complex set of data, maximum 1 minute, it was integrated in the rescheduling mechanism. If a resource changes its status due to the deplation of the inventory or to the failure of a workstation then the production is rescheduled.

Execution process with integrated part supply and operation rescheduling in case of emtpy stocks or physical failure

Last updated 29.05.2008

|