|

|||||||||||||||||

|

Tehnical data 1. Adept The robots operating in the system are controlled by the same real-time and multi-tasking operating system,V+, who manages all system level operations, such as IO, program execution, task management, memory management and disk file operations. As a programming language, V+ has a rich history and has evolved into the most powerful, safe and predictable, robot programming language available today. V+ is the only language to provide an integrated solution to all of the programming needs in a robotic workcell, including safety, robot motion, vision operations, force sensing and I/O.

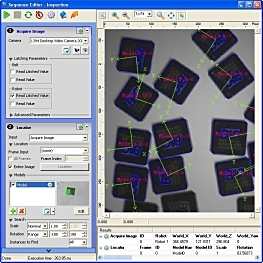

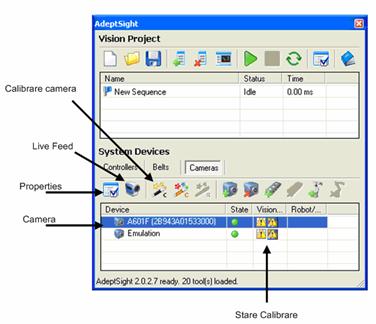

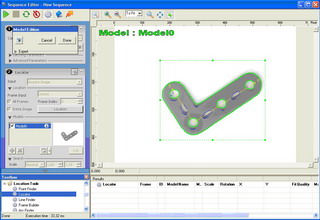

Along with the operating system V+, Adept offers another package of programs "Vision Products" who contains AdeptSight and AdeptVision. The AdeptVision sAVI Guidance option adds vision inspection and vision guidance to any AdeptSix robot, Adept SmartModules or Adept SmartMotion system. Interfacing motion and vision is simple since the vision instructions are completely integrated into V+ and AIM MotionWare. Adept's camera calibration utility supports any camera-mounting configuration and compensates for perspective distortion. AdeptSight provides easy-to-use, PC-based, vision-guidance and inspection in an out-of-the-box solution for all Adept robots, as well as a powerful framework that can be used to develop customized vision guidance and inspection applications. It allows quick development of robust and accurate vision-guided and inspection applications thanks to a simple graphical user interface. Add vision capabilities that will help you deal with smaller parts and tighter tolerances, achieve higher quality products without the need for complex programming or additional development tools. AdeptSight simplifies deployment in difficult conditions thanks to robust vision algorithms that are tolerant to poor lighting, noise, and occlusions.

Technical description

1.1. AdeptSight working procedure

4. The camera's parameters(Shutter, Gain, Brightness) must be set and then it must be calibrated.

5. The vision sequence is run in a continous loop. The robot controller connects to the computer that runs AdeptSight and takes the informations regarding the recognized pieces position. 2. Bosch IndraWorks is available as a universal, integrated engineering framework in all of our IndraMotion, IndraLogic and IndraDrive systems and solutions. The user benefits from quick, transparent access to all functions and system data for all components. Using standardized tools and interfaces, you can create solutions for all engineering tasks in a single, centralized software environment – it’s integrated, efficient and intuitive. The programming of the PLC is done with the aid of the programming language IndraLogic. After the program is written it can be tested locally, by checking the option "Online/Simulation Mode", or it can be run on the PLC by setting its IP from the communication parameters. IndraLogic main window Last updated 29.05.2008 | ||||||||||||||||