|

Formalisation of distributed production

1. Job shop description

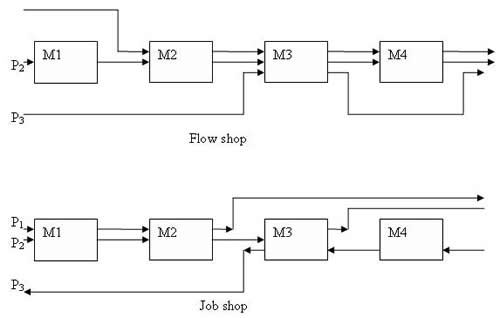

In the theory of deterministic machine scheduling, a set of parts is to be processed on a set of machines(processors) in order to minimize(maximize) a certain performance measure. A job(part) may consist of a number of operations. All machining parameters are assumed to be known in advance. Each operation is to be processed by at most one machine at a time. Depending on the way the parts visit the machines, there are two modes of processing, flow shop and job shop. In the flow shop, all parts flow in one direction, whereas in the job shop (this is what applys to the present project), the parts may flow in different directions; also, a machine can be visited more than once by the same part. In both cases, a part does not have to visit all the machines.

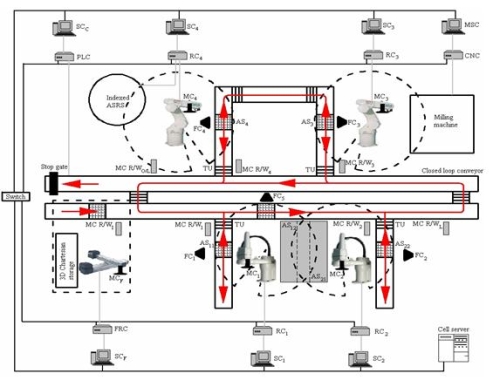

The designed flexible manufacturing system will have the structure presented in the figure below:

The assembly cell.

Considering the definition for flow shop and job shop our system will be a job shop system.

Illustration of two modes of processing: flow shop and job shop.

2. Time and resource constraints

In a set of operations precedence constraints among them can be defined. The Oi<Oj (Oi=operation i) means that the processing of Oi must be completed before Oj can be started. In other words, the set of operations is partially ordered by <. A set of operations ordered by the precedence relation is usually represented as a direct graph in which nodes correspond to operations and arcs correspond to precedence constraints. Also, time constraints can be defined, for example operation Oi must be finished within t seconds.

3. Production plans

A basic (quasi optimal) process plan and one or more alternative (sub optimal) plans are generated as Order Holons (OH) with each final product (assembly). The mounting and control resources specified by an alternative OH are at least partially different from the resources of the basic plan. The heuristic Global Assembly Scheduler uses the notations and definitions below:

O = set of all operations (assembly, conditioning)

P = set of all assemblies (final products)

OAp = set of operations for assembly Ap,p∈P

L = set of all resource types

Ql = set of resources of type l,l∈L

fi = completion time of operation oi,oi∈O

rti = remaining processing time of operation oi,oi∈O

nsip = number of successive operations of operation oi in product Ai,oi∈O,p∈P

niip = number of immediate successive operations (directly linked by precedence constraints) following operation oi in Ai,oi∈O,p∈P

niip = number of unprocessed operations in product Ap corresponding to operation Ai,oi∈O,p∈P

t = current scheduling time

rlq = resource q of type l, q∈Ql , l∈L

For the networked assembly problem, the following types of resources are defined:

- r1q = assembly robot manipulator, q=1,2: SCARA,q=3,4: vertical articulated;

- r2q = gripper, q=1,2:2(3) –finger number, q=3,4: flat / concave-contact profile;

- r3q = end-effector tool, q=1,2,3: none / bolt / screwdriver;

- r4q = physical-virtual camera duality (PiVj), q=1,2, ..., ∑nvi , 1≤j≤nvi, where nvi = number of virtual cameras defined and installed for each physical camera i , 1≤i≤9;

- r5q = magnetic code R/W device, q = 1, 2, 3, 4.

Resource rlq is operational if it can be used after a finite time delay Δlq , q∈Ql , l∈L , &Deltalq, available if Δlq=0, and down otherwise.

An assembly plan APp(δ) of a product Ap is embedded in a resulting Order Holon OH as a vector of triplets, each specifying operation number oi, processing time ti(δ) of operation oi using assembly plan δ, and set of resources Ri(&delta) to process the operation oi:

APp(δ)=[...,(oi,ti(δ),Ri(δ)),...],1≤i≤f,

where Ri(δ)={r1q|i(δ),...,r5q|i(δ)},q∈Ql,l∈L,1≤i≤f. The basic assembly plan with of as final operation is denoted by δ=b, whereas δ=a are alternative plans (b=0 , a=1, 2, ...).

Experiments showed that in most cases ti(b)≤ti(a) , oi∈O.

The production plan represents the assembly plans scheduled by the Global Assembly Scheduler on each individual machine. Based on its global image of the assembly system and the number of jobs in progress at any given time, the Global Assembly Scheduler computes the schedules in the form of assembly plans (OHs), but it does not impose its schedule to any of the individual robot-vision RH, SH resources.

Last updated 29.05.2008

|